Photolithography Essay

-

Osman Sirin

- December 25, 2022

Cutting Edge Technique of Photolithography

Photolithography Essay: Introduction

With the recent cutting-edge developments in technological research, there has now been an increasing number of cutting-edge technological assets and techniques. That is, technology has enabled us to make use of sophisticated and complex processes to make our daily life and business life more manageable. In this direction, photolithography, also known as UV lithography and optical lithography, is considered among such cutting-edge technologies, which “is a process used in microfabrication to pattern parts on a thin film or the bulk of a substrate (also called a wafer)” (Mack, 2019, n.p.). In this assignment, cutting edge technique of photolithography for 5nm (or 7nm, or 3nm) critical dimension (CD) technique is lead by ASML B.V., the worlds supply to the semiconductor industry, which is headquartered in the Netherlands has been studied. The paper also includes many aspects of this EUV (or others) based on photolithography, photoresists, light source, steps, and others. After all, along with current cutting-edge technologies, ASML is investing highly in research and development activities. That is, they try to make use of Moore’s Law as efficiently as possible, and they try to innovate even more complex procedures, as well as 3D microchip designs.

ASML Technologies, Netherlands

ASML Holding N.V. is a Dutch-based company. It is the biggest supplier of the semiconductor industry, especially photolithography systems. In its assets, integrated circuits are mainly manufactured. Also, the company is among Euro Stoxx 50 and NASDAQ-100. ASML is considered among the innovation leaders of the semiconductor technologies since 1984. The company powerfully highlights the fact that they are capable of combining hardware solutions with cutting-edge software, and they provide the latest technology assets. Photolithography, EUV lithography, DUV lithography, and metrology and inspection, and software are among the ASML’s leading and proven cutting-edge technologies (Our Technology, 2020).

In general, computer chips are produced through the machines manufactured by ASML Holding. More specifically, “patterns are optically imaged onto a silicon wafer that is covered with a film of light-sensitive material, which is photoresist” (Our Technology, 2020). The holding is such a vast and dynamic in the industry that it covered almost 70% of all worldwide sales of this technology. Nikon, Canon, and Ultratech are among its leading competitors in the market.

Accordingly, “a lithography system is essentially a projection system” (Our Technology, 2020, para. 2). More specifically, a blueprint transfers the light so that the pattern can be printed. Mentioned blueprint is almost four times larger than the intended pattern on the chip (Our Technology, 2020). Then, the system focuses the pattern onto a wafer, and the process repeats until a whole pattern is reached. An entire microchip is a pattern as long as the process is repeated at least a hundred times.

Along with current cutting-edge technologies, the company is investing highly in research and development activities. That is, they try to make use of Moore’s Law as efficiently as possible, and they try to innovate even more complex procedures, as well as 3D microchip designs (Our Technology, 2020). Significantly, the research on High-NA and EUV lithography is likely to shape the future microchip design and technology.

Basic Procedures of Photolithography

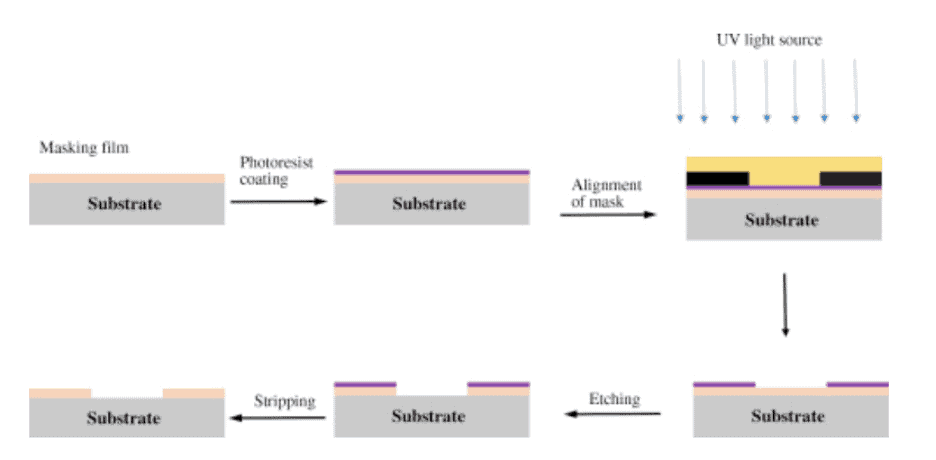

As mentioned earlier, photolithography is a complicated and sophisticated process that was introduced thanks to the development of cutting-edge technological designs. The technology makes use of the light and it “transfers a geometric pattern from a photomask to a photosensitive chemical photoresist on the substrate” (Photolithography, 2010, para. 3). Then, an exposure pattern is etched into the material upon a set of chemical implementations, and a new pattern on the desired material is enabled. The technology of photolithography is principally the same with photography because the pattern is created through the light, directly or mediately.

Fig 1. Representation of the process (Source: https://sciencedirect.com/topics/materials-science/optical-lithography)

As it is a sophisticated process, there are specific steps to be taken prior to the implementation of the technology; however, most of them are automated. The steps are cleaning, preparation, photoresist application, exposure and developing, etching, and photoresist removal, respectively (Photolithography, 2010). Suppose the water surface has a kind of inorganic or organic materials. In that case, they are to be removed with the help of chemicals, which is also called RCA process based on hydrogen peroxide. Also, depending on the preference, some other chemicals prepared with as acetone, trichloroethylene, and methanol are applicable as well.

During the preparation step, photoresist covers the wafer so that any ridge can be removed, and a flat layer is created. An evaporation process defines the level of thickness. Then, the wafer “is prebaked to drive off excess photoresist solvent, typically at 90 to 100 C for 30 to 60 seconds on a hotplate” (Photolithography, 2010, para. 9). Subsequently, a pattern of light exposes the photoresist. In general, one can readily infer that the process is quite detailed and meticulous.

During the exposure and alignment process, the wafer is located to the relative proximity to a photomask. Their locations are meticulously arranged so that there will not be any marks of misappliances during the phase. The process should be entirely accurate: not more than one micrometre, and to even 0.5 micrometres (Mack, 2019). Upon alignment, there is an immediate process with the photomask. Ultraviolet radiation is applied to a photomask, between 3 to 10 seconds (Mack, 2019). The process should be extra carefully monitored and arranged

There are generally two types of photoresists, which are positive and negative. With the negative one, ultraviolet radiation becomes polymerized (Mack, 2019). With this process, the length of the organic chain is increased, which constitute the photoresist. Thereby, the resist becomes much more insoluble and tougher. Upon the process, a replication of the pattern has been created as a result of the resisting photoresist (Mack, 2019).

On the other hand, a positive photoresist leads to an opposite type of interaction. More specifically, “exposure to UV radiation results in depolymerization of the photoresist” (Mack, 2019, n.p.). This process makes photoresist soluble, but the unexposed areas still become insoluble. Then, depolymerized or exposed parts are to be removed with the help of the developer solution. Once again, as in the previous version, a replication of the pattern has been created. After this process, to toughen the resist on the wafer, the rinsing process is started in a specific duration and temperature. This process makes adhere better to wafer, and it becomes much more resistant now. Remaining parts now should be hardened, and an oxide layer can be etched for exposure, and impurity diffusion should follow. During etching, hydrofluoric [HF] acid is used. The solution will not attack the silicon or photoresist layer. However, the duration of the process should be meticulously monitored so that there is no oxide left on the layer. The process is also called “wet etching process”. Upon etching, “the remaining resist is finally removed or stripped off with a mixture of sulphuric acid and hydrogen peroxide and with the help of abrasion process” (Mack, 2019, n.p.). However, negative photoresists are more complicated than the positive ones as they are quite vulnerable to organic solutions. After all, one can claim that the technique of photolithography is now occupying the primary preference among many other lithographic implementations across the world.

Photoresists

One can instantly claim that a large portion of cutting-edge lithography improvement has been due to the increasing qualities of photoresists. Accordingly, a sensitizer, a polymer, and a solvent system are among the leading components of a photoresist solution (Mack, 2019). When light exposes to the photoresists, energy is absorbed by sensitizer, and chemical changes in the resist are initiated (Mack, 2019). That is, “they greatly enhance cross-linking of the photoresist” (Photolithography, 2020, para. 11). Subsequently, high molecular molecules are exposed to light radiation. After all, good quality of photoresist is necessary, and its specifications are as follows: Resolution, uniform and film formation, wet and dry resistant, and good adhesion.

EUV Lithography

Extreme ultraviolet lithography (EUV) is a type of lithography processes that is usually focused on a bandwidth of around 13.5 nm by making use of the ultraviolet wavelengths. Although this technology seems to be available for mass manufacturing, merely about 60 machines are capable of producing as the technique is quite sophisticated. Also, ASML Holding is the mere producer of EUV machines within the aforementioned segment across the world (Our Technology, 2020). Resolution improvements are delivered through ASML EUV, along with DRAM roadmaps (Our Technology, 2020). In this sense, ASML Holding claims that their roadmap will eventually become much more affordable by the end of the decade.

EUV technology is a result of twenty years of constant development and R&D process of ASML Holding. In this direction, the company experienced some significant challenges including but not limited to paradigm shifts, ultra-flat multi-layer mirroring, and generating sufficient light with a high power laser. Furthermore, the company tries to develop an even more sophisticated High-NA EUV platform with faster stages and novel optics, starting at merely 3-nanometer node.

Photolithography Essay: Conclusion

Photolithography, also known as UV lithography and optical lithography, is considered among the most cutting-edge technologies. ASML Holding N.V. is a Dutch-based company. It is the biggest supplier of the semiconductor industry, especially photolithography systems. In general, computer chips are produced through the machines manufactured by ASML Holding, and it holds almost 70% of the industry. As it is a sophisticated process, there are specific steps to be taken prior to the implementation of the technology. However, most of them are automated. The steps are cleaning, preparation, photoresist application, exposure and developing, etching, and photoresist removal, respectively. After all, along with current cutting-edge technologies, ASML is investing highly on research and development activities. That is, they try to make use of Moore’s Law as efficiently as possible, and they try to innovate even more complex procedures, as well as 3D microchip designs.

References

Mack, C. (2019). The basics of Microlithography. Chris Mack, Gentleman Scientist.

Our Technology - Supplying the semiconductor industry. (2020). ASML | The world's supplier to the semiconductor industry.

Photolithography. (2010, June 1). Electronic Circuits and Diagrams-Electronic Projects and Design.

Contents

Recently on Tamara Blog

Essay on Animal Farm by Orwell – Free Essay Samples

“Animal Farm” by George Orwell is a literary masterpiece that tells the story of a group of farm animals who rebel against their human farmer and establish a socialist community based on the principles of equality and mutual respect (Orwell, 1945). However, over time, the pigs who lead the revolution gradually become corrupted by power and begin to oppress and exploit the other animals, ultimately turning the farm into a totalitarian state.

Essay on Cyberbullying – Free Essay Samples

Bullying is an aggressive behavior that is intentional and repeated, aimed at causing harm or discomfort to a person, and often takes place in social environments such as schools, workplaces, and online platforms. Cyberbullying is a relatively new form of bullying that has emerged with the widespread use of technology and the internet. Cyberbullying refers to bullying behaviors that occur online or through electronic means, such as social media, text messages, and emails.

Essay on Nature vs. Nurture – Free Essay Samples

The debate over nature versus nurture has been a longstanding topic of interest among psychologists and other scholars. The two concepts, nature and nurture, are frequently used to explain human development and behavior.

Lord of the Flies Essay – Free Essay Samples

Veterans have played a critical role in the history of the United States, serving their country in times of war and peace. Despite their sacrifices, many veterans face significant challenges, including physical and mental health issues, homelessness, and unemployment.

Why Veterans Are Important – Free Essay Samples

Veterans have played a critical role in the history of the United States, serving their country in times of war and peace. Despite their sacrifices, many veterans face significant challenges, including physical and mental health issues, homelessness, and unemployment.

American Dream Essay – Free Essay Samples

The American Dream has been a central concept in American culture for decades, representing the idea that anyone, regardless of their background, can achieve success and prosperity through hard work and determination. The concept of the American Dream is rooted in the country’s history and has been promoted in various ways, from the founding fathers’ beliefs to the post-World War II era.